Notice - I have no control over the Blogger environment in terms of

cookies and associated tracking/profiling, you should satisfy yourself

that you accept the Blogger use terms. I do not use advertising banners

or click bait to monetise my blogs. I shall consider responding to

messages but I may chose not to reply to individual messages, please do

not be offended by this in most cases I would simply rather spend time

experimenting than typing.

Introduction

You are probably reading this Blog because you have already heard of water doping or you are curious.

Basically,

water doping is a method of introducing humid air into an engine to

improve the engine efficiency, this leads to improved fuel economy,

reduced pollution, longer engine oil life, reduced carbon deposits,

cleaner DPFs and in some conditions an increase in torque.

Water doping is so simple that most do not believe that it can work or that it is beneficial to an engine.

After

five years of using water doping systems on our own vehicles we can

confirm that they work and we have experienced no detrimental effects on

the engines, in fact quite the opposite.

This technique is not new and was used

during WW2 to improve aircraft engine performance, the challenge has

always been to make a system that is simple to integrate and maintain.

Through

electrostatic charge from exhaust gas flow, water doping also polarises

the steam droplets and mist which are sucked into the engine inlet

along with the air.

The charged droplets (H2O) attach

to the fuel droplets inside the engine and being H2O (Hydrogen and

Oxygen) enhance the combustion of the fuel at the instant of ignition.

Some of the steam also gently removes carbon deposits to restore efficiency and

the mist can improve the inlet air charge density (an inter-cooler

enhancing effect). We also have seen water doping systems keep Diesel Particulate Filters (DPFs) clean.

We are keen to share our experiences to help others reduce their

pollution, below we will explain how to make an experimental water doping system.

WARNING

No Warranty is implied or given - if you experiment with Water Doping you are doing so entirely at your own risk.

The information provided is based on five years of private research and experimentation.

We

have used approved water doping systems successfully for a five year

period and over

50000 miles on our own vehicles and over 500000 miles on customer

vehicles, with a good pollution reduction and fuel savings, with no

adverse effects.

In short water doping can be

successful, but results vary from engine type to engine type, the usage

pattern, climatic conditions and the installation configuration.

Please

also note that water doping does not work well on static

engines/vehicles being tested on dynamo-meters as engines tested in these conditions are usually

earthed and therefore do not enable the build up of electrostatic charge

to help polarise the water mist/droplets.

It is possible to make

your own water doping system without buying a kit, we will explain how

to make a basic/experimental kit (which will require additional water level

maintenance) but this will allow you to satisfy yourself that the principles

work before deciding to buy a kit etc. A water doping kit which is proven is likely to be more successful

than an experimental and a kit may be a better option if you do not have time to make parts and

experiment, or you do not feel competent or confident to experiment with

your engine.

What do You Need to Make

- A device to make humid air, e.g. a bubbling container.

- A mist heater/steamer, e.g. a heat exchanger attached to a hot part of the exhaust manifold.

- Mist polarisation, achieved through the direction of gas flows (mist/air flow in opposite to exhaust gas flow).

- Venturi to introduce the mist into the inlet and create a small vacuum.

Simple Experimental Hardware

- Copper and brass plumbing pipe and fittings.

- High temperature silicon hose.

- Hose clips.

- Container approx 1 ltr capacity.

Planning the Installation

The following points need to be considered:

- Mist introduction point.

- Short hose lengths to minimise loss of vacuum and air flow.

- Container location, safe and secure, to enable topping up and to keep it warm (but not so hot that it could melt).

Please bear in mind that this

is a philanthropic act of sharing information to help everyone

interested in using water doping to reduce engine pollution and save petrol/diesel.

How to make a low budget

experimental DIY water doping system

Warning

No

warranty is implied or given. Any experimentation you decide to

undertake based on this information is done entirely at your own risk.

This part of the

Blog explains how a budget water doping system could be made to satisfy

your curiosity and prove that water doping works. It should only be

attempted by a competent engineer who understands vehicles, engines

and the terms used throughout this information. If in doubt do not

take a chance. Read all of the information first and then plan as

required.

This budget system

is not meant to be a permanent installation, but it will allow you to

make and test a water doping system before considering making your

own system or buying one (or probably a hybrid DIY and a key parts

purchase).

Parts required:

-

Qty 1 x

Plastic bottle with large screw-on top e.g. 1 pint milk

carton/bottle or a stronger bottle if possible

-

Qty 2 or 3

(depending on petrol or diesel installation) x reducing plumbing

fittings 10mm to 15mm

-

Copper pipe

sizes 10mm and 15mm

-

High

temperature silicon hose with 10mm inside diameter and a minimum of

3mm wall thickness to avoid collapse under vacuum

-

Hose clips to

suit outside diameter of silicon hose

-

Strong zip

ties to secure the bottle in place

-

Qty 2 x hose

clips to fit round the exhaust and heat exchanger

-

Qty 1 x high

flow air filter/engine breather to clamp onto air inlet

-

Qty 1 x

rubber grommet to seal inlet pipe into the bottle

-

Silicon

sealer to make joints airtight (do not put on too much and wipe of

any residue so it cant be sucked into the engine

-

Blunt vaping

needle approximately 2mm outside diameter (for petrol engines only)

-

Vacuum hose

10mm outside diameter (for diesel engines only)

Tools required:

-

Hacksaw,

suitable for cutting brass and copper

-

Files for

removing burs and shaping parts

-

Screwdriver

for hose clips

-

Method of

flattening part of the 15mm copper pipe to make heat exchanger

(hammer & anvil or a vice or similar)

-

Spanners for

tightening the plumbing fittings

-

Drill and

drill bits for making holes (probably one stepped drill bit and a

2mm drill bit will suffice)

-

1mm to 2mm

diameter steel wire/rod to maintain air gap while flattening copper

pipe to make heat exchanger

Plan the

installation

Find the hottest

part of the exhaust (normally the manifold), if possible chose a

location next to the first lambda sensor (if the engine has one).

Find a location for

the water bottle, ideally this should be somewhere warm but also

accessible for topping up and not too far from the exhaust hot spot. It is also wise to seek a location lower than the mist introduction point into the engine.

Select the mist

introduction point, for normally aspirated petrol engines the engine

breather pipe is usually the best point of mist introduction, for

turbo diesel engines just before the turbo is good as this

installation relies on air flow to create vacuum. Turbo petrol

engines are difficult to get working properly so are probably best

avoided at this time in your project.

You must avoid all

moving and other hazardous parts. Also take account of engine rock

during operation when routing hoses.

Make the parts

Bottle/bubbler

Mist outlet

Take one 10mm to

15mm plumbing fitting and remove the 15mm end nut and cut off the

outer flange so that it can be used as a nut to clamp it to the cap

(alternatively you can use packing washers to take up the gap).

Fix approximately a

50mm long piece of 10mm copper pipe to the smaller end of the fitting

(this is to be able to connect the silicon hose to the bottle cap).

Drill a hole in the

bottle cap and insert the fitting from the outside and secure on the

inside with the modified nut and silicon sealant.

Air inlet tube

Take a piece of 15mm

diameter pipe long enough to be inserted through the top of the

bottle (at a point where the grommet can be fitted and sealed) to

reach the bottom of the bottle and protrude sufficiently at the top

to fit the breather/filter. Drill a suitable size hole in the bottle

for the rubber grommet and fit the grommet with a small amount of

silicon to make a good air tight joint.

Perforate the bottom

end of the pipe with Qty six x 2 – 3mm holes suitably space in the

bottom 20mm of the pipe (this is to create small bubbles which are

better than big ones). De-bur all parts and remove any swarf. Insert

the the pipe with the small holes at the bottom and seal to the

gromet with a small amount of silicon sealant.

Heat exchanger

Check the available

space on the exhaust hot spot, try to find approximately 150mm long

area to clamp the heat exchange to. Cut a piece of 15mm diameter

copper pipe to suit the space available less the length of two

fittings (one secured at either end of the pipe). Secure the fittings

to the pipe and tighten the nuts on the 15mm ends then remove the

10mm end nuts and olives. Insert two lengths of welding rod through

the assembled fittings and pipe, then flatten the pipe using the rods

as a guide, do this carefully as you need to be able to pull out the

rods afterwards. Do not flatten right up to the fittings at either

end as this will damage the air tight seal (stop about 30mm short of

the nuts). Once the pipe has been flattened, gently bend (do not

kink) it into a shape that enables the flat part can sit snug against

the exhaust with the fittings standing clear to enable the hoses to

be connected without fouling other parts. Once you are satisfied with the fit extract the rods. Clamp the heat exchanger in

place with suitably sized metal hose clips (ideally stainless steel and

these will be easier to remove later).

Petrol engine mist

Injector

Take the vaping

needle and insert it through the 10mm OD vacuum tube so that

approximately 10mm of tube is exposed at the other end. Insert the

assembled vaping tube and hose into the end of the 10mm ID silicon

hose and secure it with a hose clip about 10mm back from the end of

the silicone tube (to leave space for another clip) ensure that it

has an air tight seal and cannot be sucked into the engine. Take

another hose clip and clip two zip ties to the hose on opposite sides

so that these can be used to secure the needle into the engine

breather pipe. Pierce or drill the engine breather pipe and insert

and secure the injector needle with a small amount of silicon sealant

on the mating faces.

Diesel engine mist

injector

Please note that you must not blank off more than 25% of the inlet hose/duct cross sectional area with the venturi.

Take a piece of 15mm

pipe and cut half of it away (to make a half pipe venturi) for a

length approximately equivalent to the inside diameter of the inlet

duct/hose it will be inserted into, less 5mm (depending on inlet

hose/duct thickness) to leave clearance on the far side and provide a

circular sealing surface where it is inserted into the inlet

duct/hose. De-bur and remove swarf as necessary. Trim and fit the

pipe to a 15mm fitting so that a seating area just larger than the

thickness of the wall of the inlet hose/duct protrudes from the

fitting. Tightly secure the pipe to the fitting so that the pipe

cannot be sucked into the engine. Fit the 10mm diameter copper pipe

to the fitting and insert the pipe into the silicon hose. Secure the

hose to the pipe with a hose clip and add a second clip to the hose

closer to the fitting with two zip ties on opposite sides so that

these can be used to secure the injector/venturi into the engine

inlet hose/duct. Drill the inlet hose/duct to accept the injector as

a snug fit, fully insert the injector with a small amount of silicon

sealant on mating faces.

Connect up

Good unrestricted

air flow is key to success. Hoses should be kept as short as possible

and have no sag that could lead to water traps and ice plugs if

weather is freezing over night etc. The hoses should also not be

allowed to kink, add support if necessary but avoid clipping the

hoses in a way that could restrict air flow.

The air flow through

the heat exchanger needs to be flowing in the opposite direction to

the exhaust gas flowing inside the pipe that the exchanger is secured

to, so trim and connect the hoses with this in mind.

Take the hose from

the mist injector and secure it to the the heat exchanger, connect

another piece of hose between the heat exchanger and the the bubbler

bottle top outlet.

Filling the system

and testing

Fill the bottle with

demineralised, distilled or rain water(depending on your installation

it might be easiest done by removing the air filter/breather and

pouring water through the tube) to approximately 25mm above the

highest hole on the inlet tube (so that any air has to bubble through

at least 25mm of water).

Start the engine and

check that the system is bubbling (Diesel engines may not bubble

until above approximately 1500 rpm, if it doesn't bubble then you might need to blank the EGR) and check that the bottle is not

collapsing etc.

Run engine until the

engine it is hot, checking the security of parts etc. as necessary.

Allow the engine to cool and then check all fittings are tight and

secure. Test as you desire – if driving you should notice an

improved driving experience, if you enjoy this too much you will not

see a fuel saving as you will be using more power.

Hopefully

you will find this of some interest or use. Please don't wast your time

adding critical comments as this is free information that could help

some people to reduce engine pollution and save fuel on engines.

If

you do make a saving on fuel, perhaps you would consider making a small

donation, so that I can improve the system design and offer more free

info. Leave a message sharing your experiences and let us know if you would like to donate or contribute

positively to further developments in other ways.

If you are based in

the UK and do not fancy making your own water doping system, I may be able to help. Bespoke systems can also be designed/made

on request e.g. for long range trucks, Porsche Boxsters and tractor engines etc.

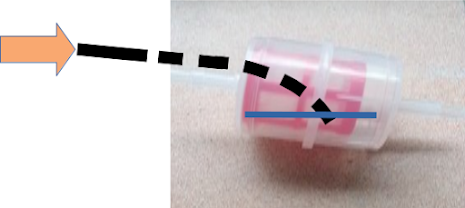

Photos

I have taken some photos of various parts from my experimental equipment (more to follow when I find the other original parts from 6 years ago):

Example of 15mm to 10mm reducing plumbing fitting

10mm end of pipe fitted with silicon hose

Fittings in plastic bottle cap

Using a larger cap size allows both fittings to be inserted in it so the bottles can be removed for easier filling. Also plastic pipe can be used for the fittings at the bottle end as it does not get hot, I used it for the inlet as it is easy to drill for the bubble holes.

Plastic tube drilled for bubbling

Ensure all swarf and burs are removed. The plastic tube can rest on bottom of bottle (but do not seal the end). The small tube is flush with the underside of the filler cap.

Cap assembly fitted to the bubbling bottle

I tried to find the most robust bottle and this on is a sample bottle, it is also the same diameter as most drinks bottles found on cycles so it could be mounted with the same sort of bracket (with an additional retaining strap to stop it jumping out of place).

10mm ID high temperature Silicon hose fitted over outlet tube

The 15mm plastic pipe can be fitted with a free flow engine breather/filter to stop ingesting particles if you run out of water.

Add hose clips to all fittings and ensure there are no air leaks.